We’re Here to Help with Your Toughest Wastewater Challenges

You know that lowering management costs is about more than simply reducing the need for electricity. Eliminating hauling costs, chemical costs, and the need for onsite personnel (all in an OpEx format) means that you don’t have to make a costly CapEx investment.

Guarantee Permit Compliance

Never worry about compliance risks and penalties again. We know our system works – that’s why we offer a compliance guarantee!

Mitigate Carbon Emissions

Mitigate up to 90% of GHG emissions from wastewater treatment and recover direct electricity with no methane production. Plus, with reduced energy consumption, you can achieve Scope 1, 2, and 3 emission reductions.

Reliable System Performance

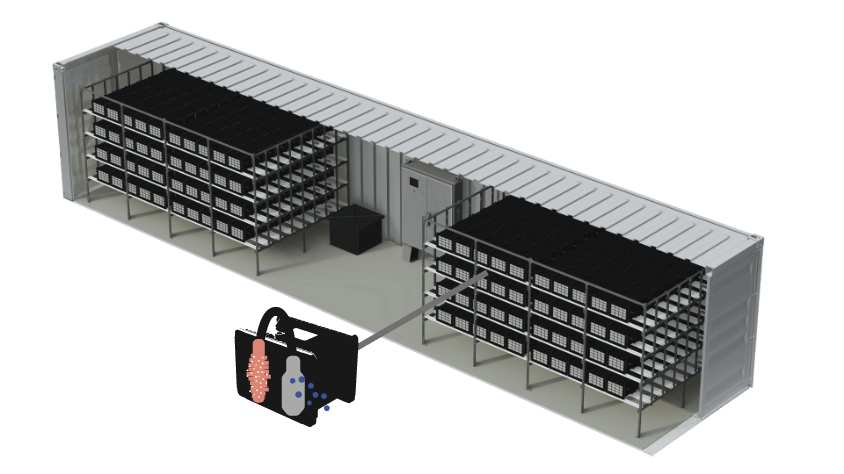

Tired of dealing with the uncertainty of variable production environments? Our BETT system is resilient to changes in production, handling wide fluctuations in volume, temperature, BOD, and TSS.

Quick Results

Accomplish in hours what it would take days for conventional wastewater systems to treat. We keep our bugs hungry so they’re always ready to clean tough-to-treat high-BOD wastewater.

24/7 Remote Monitoring and Control

Catch issues before they become a problem. Our wastewater experts remotely monitor and control your system 24/7 so you can focus on your core business.

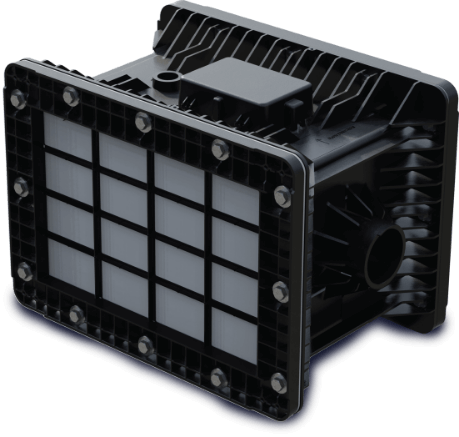

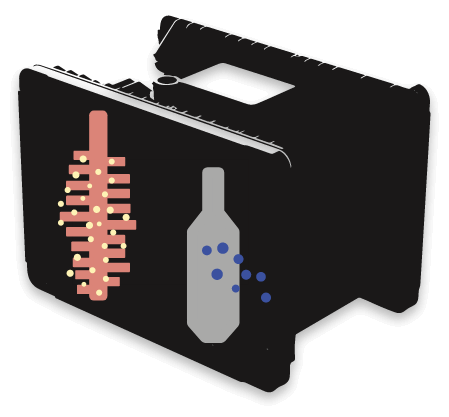

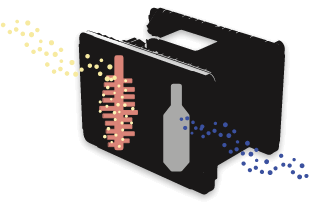

A look into the little black boxes that power our BETT system.

Compare BETT

with Other Technologies

| Metric | Aquacycl BETT | High-rate Anaerobic Digestor |

|---|---|---|

| BOD concentration (mg-BOD/L) | 500- 150,000 | 1500 - 25,000 |

| Maximum TSS concentration (ppm) | 3,000 | 300 |

| Maximum FOG concentration (ppm) | 300 | 50 |

| Hydraulic Residence Time (hours) | 4 - 18 | 8 - 48 |

| Organic loading rate (mg/L-BOD per day) | 5 - 150 | 0.2 - 13 |

| Energy consumption (kW/kg-BOD treated) | 0.2 - 0.4 | 0.8 - 1.2 |

| % Sludge (Biomass/BOD treated) | 0.7% | 10% |

| Operating pH range | 5 - 9 | 6.5 - 7.5 |

| Operating temperature | 10 - 50 oC | 32 - 40 oC |

| Minimum availability* | 87% | 0% |